Shipping containers are an essential part of global trade, providing a standardized method for transporting goods across oceans, railways, and highways. If you’re looking to understand shipping container dimensions and how they might suit your needs, this comprehensive guide covers everything you need to know.

What Are Shipping Containers?

Shipping containers are large, standardized boxes made from steel or aluminum that are used for transporting goods. They are designed to withstand harsh environments while ensuring the safety of the cargo. From sea freight to modular construction, their versatility makes them indispensable in various industries.

Standard Shipping Container Dimensions

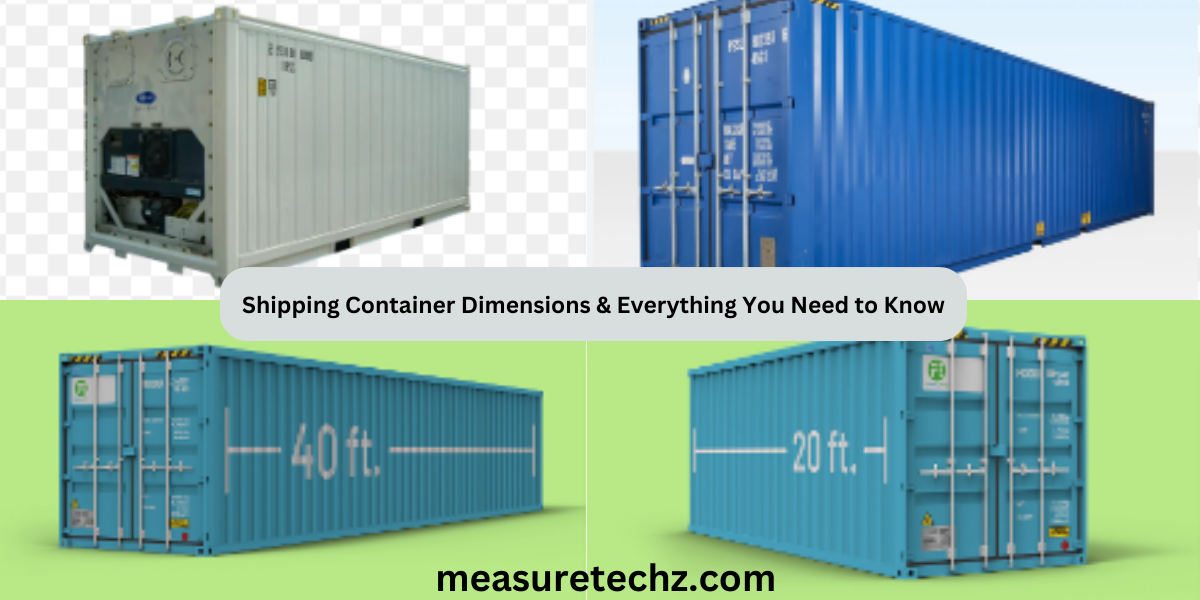

Shipping containers come in various sizes, but the most commonly used are 20-foot and 40-foot containers. Here’s a breakdown of their dimensions:

1. 20-Foot Shipping Container

External Dimensions:

- Length: 20 feet (6.058 meters)

- Width: 8 feet (2.438 meters)

- Height: 8 feet 6 inches (2.591 meters)

Internal Dimensions:

- Length: 19 feet 4 inches (5.898 meters)

- Width: 7 feet 9 inches (2.352 meters)

- Height: 7 feet 10 inches (2.393 meters)

- Volume Capacity: Approximately 33.2 cubic meters

- Weight Capacity: Up to 28,200 kilograms (62,170 pounds)

2. 40-Foot Shipping Container

External Dimensions:

- Length: 40 feet (12.192 meters)

- Width: 8 feet (2.438 meters)

- Height: 8 feet 6 inches (2.591 meters)

Internal Dimensions:

- Length: 39 feet 5 inches (12.032 meters)

- Width: 7 feet 9 inches (2.352 meters)

- Height: 7 feet 10 inches (2.393 meters)

- Volume Capacity: Approximately 67.7 cubic meters

- Weight Capacity: Up to 28,800 kilograms (63,490 pounds)

3. High Cube Containers

High Cube containers are a variant of standard containers with an extra foot in height, making them ideal for cargo that requires additional vertical space.

- Height: 9 feet 6 inches (2.896 meters)

- Volume Capacity: Approximately 76.4 cubic meters (40-foot High Cube)

Specialized Shipping Containers

1. Refrigerated Containers (Reefers)

Used for transporting perishable goods, reefers maintain a controlled temperature range, typically from -25°C to +25°C.

2. Open-Top Containers

Designed for oversized cargo that cannot be loaded through the doors, these containers feature a removable top.

3. Flat Rack Containers

Ideal for heavy or oversized goods, flat racks lack side walls and a roof.

4. Tank Containers

Used to transport liquids, gases, or powders, tank containers are made of stainless steel with an exterior frame for protection.

Factors to Consider When Choosing a Shipping Container

1. Purpose

- Transportation: If you’re moving goods, focus on the container’s dimensions, weight capacity, and durability.

- Storage: Consider insulation and ventilation if the container will house temperature-sensitive items.

- Construction: High Cube containers are ideal for building modular structures due to their extra height.

2. Regulations

Ensure compliance with local and international shipping standards. Check for ISO certification, which guarantees the container meets global quality standards.

3. Condition

- New vs. Used Containers: New containers offer better durability, while used containers are more cost-effective.

- Inspection Points: Check for rust, dents, and door functionality.

4. Budget

Shipping container prices vary based on size, condition, and type. A standard 20-foot container typically costs between $2,000 and $4,000, while specialized containers can be more expensive.

Common Questions About Shipping Containers

1. How Many Pallets Fit in a Container?

- 20-Foot Container: Fits 10-11 standard pallets (48″ x 40″).

- 40-Foot Container: Fits 20-21 standard pallets.

2. Can Containers Be Customized?

Yes, shipping containers can be modified for various uses, such as homes, offices, and pop-up shops. Common customizations include insulation, windows, and electrical wiring.

3. Are Containers Waterproof?

Yes, standard shipping containers are designed to be weatherproof, protecting cargo from rain, snow, and sea spray.

4. How Long Do Shipping Containers Last?

With proper maintenance, a shipping container can last 20-25 years or more.

Sustainability and Reusability of Shipping Containers

Shipping containers contribute to sustainability when repurposed for:

- Modular housing

- Mobile offices

- Storage units

By recycling containers, you reduce waste and the environmental impact of manufacturing new materials.

Conclusion

Understanding shipping container dimensions and types can help you make informed decisions for your business, construction project, or storage needs. Whether you’re transporting goods across the globe or building a container home, selecting the right container ensures efficiency and cost-effectiveness.

For expert advice or to explore our range of shipping containers, contact us today. Let us help you find the perfect solution tailored to your needs!